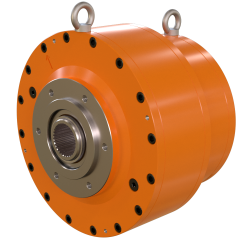

Separating solids from liquids is essential in many industrial processes. Servotak SD Centrifuge Reducers are the perfect drives for decanters with bowl and screw conveyor and centrifuge machines.

Servotak SD Centrifuge Reducers' high quality is due to a combination of innovation and years of experience in planetary transmissions.

SD Centrifuge Reducers provide both the differential speed between the bowl and the conveyor, and the torque for the screw conveyor. A circular, carefully balanced design ensures a vibration free centrifuge machine operation. The housing is affixed to the bowl thus turning at the bowl speed. The centrifuge reducer output shaft is connected to the conveyor and transmits the torque necessary for solids transportation.

Calculate your machine and find the required gearbox output torque using this tool