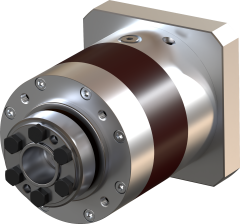

GSAH-250 Planetary Gearbox

GSAH-250 Planetary Gearboxes can output up to 287 Nm (depends on ratio), and are suitable for servomotors up to 5kW. Their output bearings are allow for higher radial loads than equivalent gearboxes. Thanks to synthetic oil lubrication, the gears are better lubricated, better cooled, and run more smoothly. Under extreme conditions such as very high cyclic rates, GSAH-250 gearboxes are the perfect option.

Calculate your machine and find the required gearbox output torque using this tool