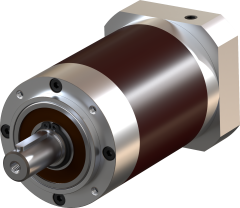

GSB-050 Planetary Gearbox

GSB-050 Planetary Gearboxes can output up to 73 Nm (depends on ratio), and are suitable for servomotors up to 600W. Their output bearings allow for higher loads than GSA-050 gearboxes. This makes them suitable for helical rack&pinion systems up to module 2. They're maintenance free thanks to lifetime lubrication.

Calculate your machine and find the required gearbox output torque using this tool