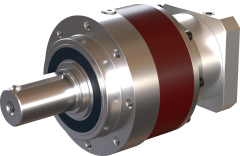

GSE-250 Planetary Gearbox

GSE-250 Planetary Gearboxes can output up to 377 Nm (depends on ratio), and are suitable for servomotors up to 5kW. Their output bearings are allow for medium-high output loads. Thanks to synthetic oil lubrication, the gears are better lubricated, better cooled, and run more smoothly. Under extreme conditions such as very high cyclic rates, GSE-250 gearboxes are the perfect option.

Calculate your machine and find the required gearbox output torque using this tool