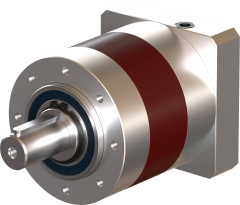

GSA-080 Planetary Gearbox

GSA-080 Planetary Gearboxes can output up to 168 Nm (depends on ratio), and are suitable for servomotors up to 2kW. Their output bearings are appropriate for moderate radial loads. They're maintenance free thanks to lifetime lubrication.

Calculate your machine and find the required gearbox output torque using this tool